We deconstruct an old termite infested and water damaged shed.

We deconstruct an old termite infested and water damaged shed.

A homage to the Eco Friendly Shipping Container Home and Container Architecture. Here are 15 Iconic Residential Eco Shipping Container Continue reading

Codex Box? Shipping Container Homes-

Codex Box? Shipping Container Homes-Ok you are here for information on “Codex Box”. The reality is I had never heard of a codex box until I started getting into Shipping Container Homes. In most instances a Codex Box is another name for a Shipping Container. Just like the regular shipping container they are modular. Meaning they are uniform in sizes and weights. It appears that the term “Codex Box” is a conjunction of container express box. That only makes since.

Codex Box homes and Shipping Container Homes came out of necessity. Ports all over the world began seeing stacks and stock piles of a banded Codex Boxes. So what do you do with them?

The first idea was to sell them to scrap yards. This is a good idea until the price of steel took a dive. So as people do they started thinking of what they could do to increase the value of the codex box. Never discount the ingenuity of people. Out of necessity ideas happen.

The first idea of turning a codex box into a habitable home probably came from the back roads somewhere. I don’t know of how many shipping containers I have seen going through the back roads. It seems that rural areas have had ideas on how to re-purpose codex boxes for as long as they have been in existence.

Think about it for a minute. People have been living in modular dwellings (homes) since the turn of they last century. Certainly codex boxes meat the same definition of a module. Now lets look at some of the finer points of having a codex box as a home…

Like I said at the beginning of this article, Codex Boxes are the same as Shipping Containers. That means anything you can do with a shipping container you can also do with a codex box!

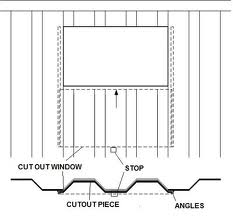

Shipping Container Homes – Adding Windows and Doors

Shipping Container Homes – Adding Windows and Doorsis really not all that difficult. I think what intimidates people is the fact they are working with steel. I to was intimidate of working with steel coming form a carpenter back ground. After I began working with steel more and more I found I actually like it better.

The main thing with working with shipping container homes and its steel exterior is you have to measure twice before you make a cut. The second thing you have to consider is what kind of interior trim are you going to use.

When you start your search for your doors and windows be sure to only look for “flanged or finned” type. Look for the ones with fixed flanges or fins. The other type is flanges and fines that you have to install in a grove in the window or door frame. The reason I don’t care for this type is they need an extra step that we don’t have to ensure they don’t leak.

The type of framing you use will largely be dictated by your furring size. If you are using 2×4 pt for your furring, this is what you will use for your windows and door frames. The only difference is how you are will attach the frame to the container. I always use liquid nails and caulking.

The hole size will be 1/8″ larger than the door or window its self (not the flange/ fin). The door and window will be installed from the out side. I generally use again, liquid nails and caulking for the install. I never use screws unless it is absolutely necessary. Some time the exterior of the container gets ripples and makes it necessary.

The frame of course will be installed from the inside on the shipping container. The frame size will be dictated by the type of interior your shipping container home will have. You need to plan out if you want the interior trim to die into the window or fit snug between the window and the wood frame.

If you are going to install an exterior trim around the openings it would be a good idea to ad flashing around the fins of the doors and windows. Most flashing now days are the peel and stick type. I tell you I like this a lot better than the old metal ”Z” flashing. The biggest advantage is it just sticks. It neve made since to me to have to penetrate flashing with screws or nails. To me that is just another place that water can find a place in.

There are other ways to install windows and doors into your shipping container home but these are the ways that have worked for me. I you have any question on how Shipping Container Homes Windows and Doors installation just shoot me an email.

Shipping Container Homes Foundations

Shipping Container Homes FoundationsChoosing a foundation for your shipping container home can be challenging. There are some guidelines to consider to make it easier. Of course location is the number one concern when choosing the foundation. Lets go through a few scenarios, but before we go any further always consult a local engineer for the specifics in your area.

This is just like what it sounds like “on grade”. On grade means on the ground. What you would normally do is have the bottom of the storage container a minimum of 8″ above the highest elevation of the ground.

In Florida where I live we use 2,000 s/f compaction as a base line, again you may have to consult with an engineer. Also we are figuring a 8″ x 40″ (320 s/f) container. We also are using a dead load of 35 lb s/f and a line load of 40 lb s/f for a total of 75 lbs s/f. If we multiply that times the floor area (75 x 320 = 24,000 lbs. This is important because we have to size the foundation accordingly.

There are basically two types of pads. Poured in place and Precast. Either one will have to be in the ground. The depth in the ground depends of your geographical location. Frost lines is the big determining factor. Believe it or not Florida has a 12″ frost line. That means any foundation that is going into the ground has to be a minimum of 12″ into the ground. The further north, the deeper you have to go. Check your area.

As for size of the pads this is where the loads come into play. We are going to use the total load of 24,000 lb s/f. The pads sizes are going to be based on the total amount you want to use. Example: We want to use 8 pads, we would divide the 24,000 by the amount 8 which comes to 3,000lb load on each pad. Now remember the soil compaction of 2,000 lb s/f? So we will divide 3,000 lb s/f (load each pad) by 2,000 lb s/f (compaction of one s/f of soil) or each pad needs to be a minimum of 16″ x 16″ . The height is not that important but has to be able to support 3,000 lbs. There is another consideration and that is “topple factor”. This is the amount of force it will take to “topple” the shipping container home over.

Piers are like pads but generally are “above” grade. These should be sized in the same way as the “pads”. I would recommend no smaller that 16″ x 16″ and no less than 8 piers. Just like with the pads it is very important to “tie” the shipping container home down according to your location.

A spread footer is the term used for the common 16″ x 10″ footer used on stem wall construction. The footer is continuous and reinforced with (2) #5 rebar. Generally the minimum concrete compression is 2,500 psi s/i.

This kind of foundation is good if you are wanting your shipping container home more permanent. This is also a good method to raise the home and have storage below.

These are three of the more common foundations for shipping container homes. Of course there are others. I will make mention that you can use timbers and they work quit well.

If you have any question on foundations for your shipping container homes just give me an email.

The voters overwhelmingly approved a ballot initiative to not let Sharia Law be used in the Oklahoma courts. the Continue reading

Just a few thing to look out for when buying a shipping container.

Don’t get ripped off !

Link for Continue reading

Battle of New Orleans.

VR 1TacticalMedic

I have 4 growing seasons in my neck of the woods and this is what I’ll be growing this winter.